Here are the eight rules used to identify an out-of-control condition. Some of these patterns depend on certain “zones”.įig: Sample SPC chart with zones ( Source) Recognizing these patterns is the key to finding the root cause of special causes. Once you’ve plotted the data points, you can start to see patterns in them. LCL = average - 3 x σ Step 4: Plot Data Points and Identify Out-of-Control Data PointsĪfter establishing control limits, the next step is to plot the data points on the SPC chart.

Some of the most popular ones are Nelson tests and Western Electric tests. There are a number of tests that are used to detect an “out of control” variation.

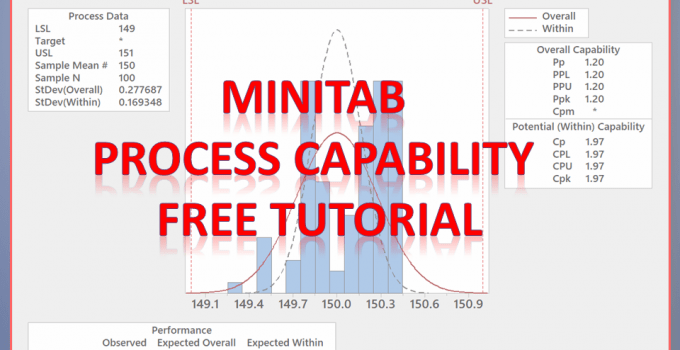

CPK CALCULATIONS IN EXCEL FREE SOFTWARE UPDATE

Once the formulas and meaning is understood, you can use statistical software to update them. It is best to plot the data points manually in the early stages of making an SPC chart. If there are data points outside of these control units, it indicates that a process is out of control ( special cause variation).įig: Control limits of an SPC chart ( Source) If the data points are within the control limits, it indicates that the process is in control ( common cause variation). What Are Control Limits?Ĭontrol limits are the standard deviations located above and below the center line of an SPC chart. Interested in learning Lean Six Sigma and its importance? Check out the Lean Six Sigma Green Belt Certification course preview. Nowadays, SPC charts have been incorporated by organizations around the world as one of the primary tools to monitor and improve the control of a process. Edwards Deming when he introduced the concept to the Japanese industry after World War II. This is why they are also known as Shewhart charts. Shewhart of Bell Laboratories in the 1920s.

SPC charts were initially developed by Dr. The three main components of an SPC chart are - a central line (CL) for the average, a lower control line (LCL) for the lower control unit, and an upper control line (UCL) for the upper control unit. All the data generated from the process are plotted in time order. What Are SPC Charts?Īn SPC chart is used to study the changes in the process over time. Statistical Process Control or SPC is a statistical method of using the data generated by a process to control and improve it continually. In addition to this, processes generate a lot of data as well. Every process is designed to generate output - either a product or a service.

0 kommentar(er)

0 kommentar(er)